In short...

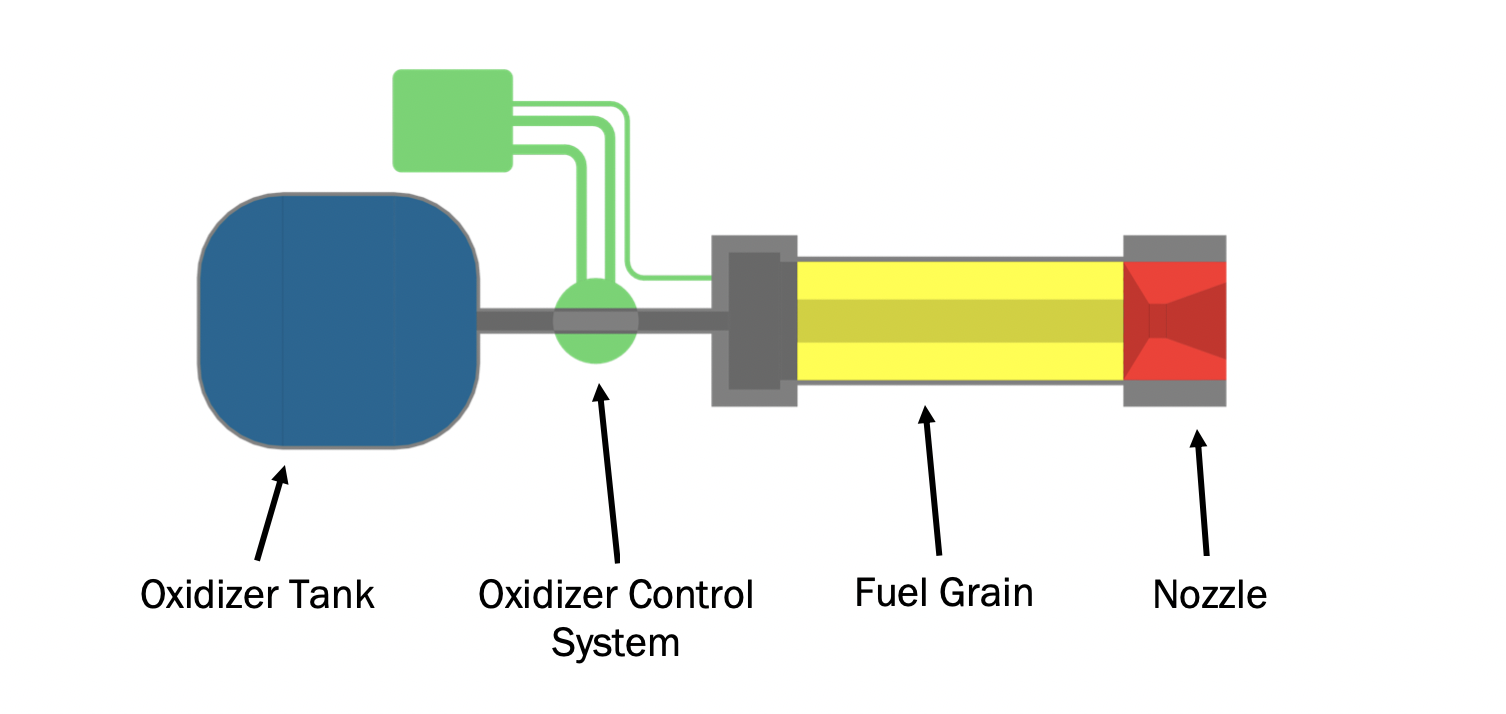

For my dissertation, I am looking into how 3D printing can be used to improve the performance of hybrid propellant rocket engines. A Hybrid propellant rocket is an alternative type of rocket engine that uses two propellants, one is a liquid or gas, the other is a solid material. Rockets traditionally use either all-solid propellants, or all-liquid propellants. Each have benifits and drawbacks. Hybrid rockets seek to combine the benefits of both simple, solid rocket motors, and high-performance, liquid rocket engines. However, hybrid rockets have many areas for improvement, one such area is the difficulty of controlling their thrust without adding too much complexity - a problem that I am aiming to demonstrate a solution to with this project.

SUMMARY OF MY PROJECT

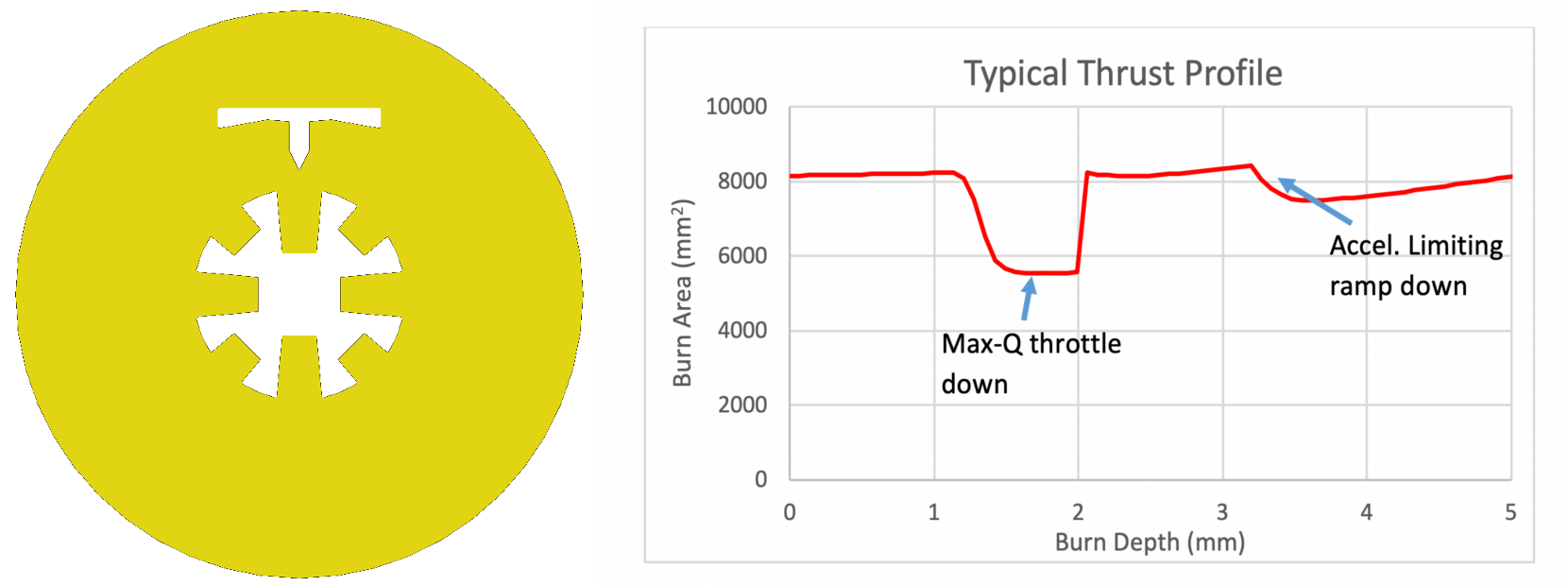

The solid fuel grain of the hybrid rocket is typically made from a polymer with a specially shaped hole, known as the fuel port, down the middle of the structure. The fuel port burns outwards along its length and its shape can be designed to produce different thrust profiles for different applications. The complexity and flexibility of the fuel port geometry is limited by the manufacturing technique - my project makes use of 3D printing to all but remove these limitations. This concept has the potential to allow hybrid rocket engines to have their fuel grains optimised and printed for specific missions, all while not requiring different manufacturing hardware - no moulds or formers are needed for 3D printing!

My project will involve the design, manufacture and test-fire of several different 3D printed fuel grains using the new rocket test cell at the Roehampton Vale campus, as well as the NYX-100 hybrid rocket and test stand designed by the BEng students on my course. The aim is to demonstrate throttling behaviours commonly used in liquid rocket powered launch vehicles, such as a load-limiting thrust reduction early on in the burn, and a controlled, acceleration-limiting ramp down towards the end of the burn. The geometry of the fuel port will provide these actions, and parameters such as thrust level and timings will be changed for each test fire to demonstrate how a 3D printed fuel grain can be tuned to the specific requirements of a mission.

WHO AM I?

I'm Tom. I am a 3rd year MEng student studying Aerospace Engineering, Astronautics and Space Technology at Kingston University. I have been interested in spaceflight and rocket propulsion for as long as I can remember!

WHERE WILL THE MONEY GO?

If the funding target is reached, the money will be primarily used to fund the 3D printing of the fuel grains themselves. I wish to test 3 different thrust profiles, with an additional control test to ascertain the combustion behaviour of the material. In total 4 fuel grains are needed for my project! The fuel grains are quite large, at 70mm diameter and 200mm length and are printed from mostly solid ABS plastic. Each grain weighs in at approximately 500g - 750g. ABS printing is priced at 10p/gram meaning that each grain will cost approximately £50 - £75. Using data from the preliminary fuel grain designs, the estimated cost for printing is around £225.

The excess money will be used to finance the production of any additional components needed for testing, such as rocket nozzles, as well as the production of the backer rewards. More fuel grains will be printed and tested to gain more data if the funding (and my schedule!) allows.

In summary that's...

- 3x test grains - approx. £75 each

- 1x control grain - approx. £50 each

- Additional components and backer rewards - £25+

TOTAL: £300

Ideally, I would like to test each fuel grain twice requiring 6 test grains and 2 control grains, making the budget for 3D printing £550. An extra £50 is added to this total to allow me to fulful the backer rewards, as there will be more to fulfil if this level of funding is reached! Because of this, the overall funding target is set at £600.

REWARDS

Please note, work on physical rewards will not begin until the summer of 2020 to give me time to work on the project itself as well as my other commitments at the University.

Help me succeed!

All donations are greatly appreciated! If you are unable to donate, sharing this page is also very helpful and is also much appreciated!

Thank you!

Tom